Major Causes of Plastic Settlement Cracks:

- Reduction in the volume of the cement-water system due to bleeding and segregation

- Internal restrainment due to reinforcement steel or large size aggregate

- External restrainment due to relatively narrow formwork

- Pronounced change of concrete cross section

- Absorbent sub base or formwork surface

- Flared column heads, troughs and waffles in floor slabs

What are plastic settlement cracks in concrete?

Plastic settlement cracks in concrete are formed during initial setting of concrete. Mechanism, appearance and prevention of plastic settlement cracks are discussed below. If the settlement of solids in the concrete can freely take place without hindrance there will be a reduction in depth and volume of the cast concrete but no cracking.

How long does it take for plastic settlement cracking to appear?

The earliest form of cracking is termed plastic settlement cracking and may be apparent within ten minutes to three hours after placement. Plastic settlement cracks are due to excessive bleeding accompanied by restraint.

What is plastic shrinkage cracking?

WHAT is Plastic Shrinkage Cracking? Plastic shrinkage cracks appear in the surface of fresh concrete soon after it is placed and while it is still plastic. These cracks appear mostly on horizontal surfaces.

Where do cracks occur in a settlement Slab?

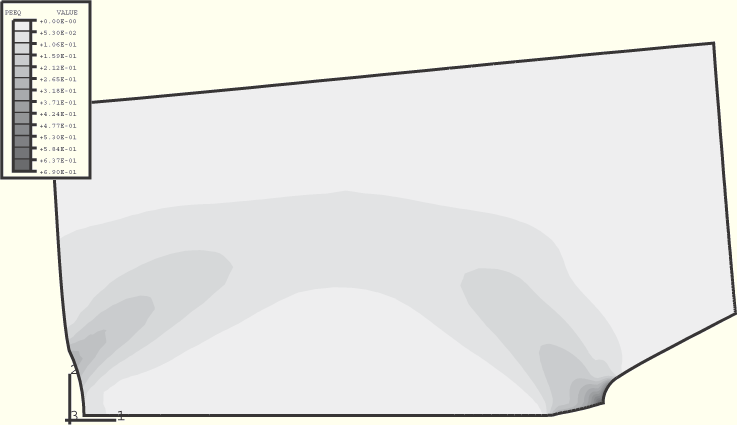

Visual appearance of Plastic Settlement Cracks The most common restraint in slabs is from the reinforcement. The cracks occur on the top surface and usually follow the line of the uppermost bars, giving a series of parallel cracks; there may also be shorter cracks at right angles over the bars running in the opposite direction.

What is settlement cracking?

Settlement cracks are the result of the home settling onto its foundation. Typically, these cracks appear at the weakest points of a structure – namely, windows and doors.

How do you fix plastic settlement cracks in concrete?

The Plastic shrinkage/Plastic Settlement may be repaired in plastic state by reworking the concrete surface using surface vibrators to close the cracks over their full depth and then completed by surface finishing.

What is the key difference between plastic shrinkage cracking and plastic settlement cracking?

Five different cracking behaviours of plastic concrete have been identified. No cracking in conditions with low evaporation and differential settlement. Pure plastic settlement cracking show internal cracks and multiple surface cracks. Pure plastic shrinkage cracking shows sudden single cracking through the slap depth.

Are settlement cracks serious?

It's even normal to see a few cracks as the house settles fully into its new plot. These cracks will most likely appear where the wall meets the ceiling, but small foundation cracks are not uncommon. Of course, any visible cracks should be filled with a concrete sealer as soon as you notice them.

What causes plastic settlement in concrete?

Cracks caused when the settlement of fresh concrete is restrained by reinforcement or formwork. Plastic settlement cracks can form in young concrete, within the first few hours after placing. As water moves upward through the mixture, the denser constituents move downward.

What will reduce the risk of plastic settlement cracks in a slab?

The restraints that cause plastic settlement cracking are inherent in the construction and generally cannot be avoided. Abrupt changes in section depth could be avoided at the design detailing stage but the main reduction of risk is through mix design and suitable cohesion of the concrete to reduce bleeding.

What causes plastic shrinkage?

Plastic shrinkage is caused by the loss of water by evaporation from the surface of newly laid concrete or by suction of dry concrete underneath. At the surface, plastic shrinkage occurs when the rate of evaporation exceeds the rate of bleeding.

What causes shrinkage cracks?

Plastic shrinkage cracks are caused by a rapid loss of water from the surface of concrete before it has set. The critical condition exists when the rate of evapora- tion of surface moisture exceeds the rate at which ris- ing bleed water can replace it.

How do you stop plastic shrinkage from cracking?

Follow These Rules to Prevent Plastic Shrinkage Cracking Dampen the subgrade and forms when conditions for high evaporation rates exist. Prevent excessive surface moisture evaporation by providing fog sprays and erecting windbreaks. Cover concrete with wet burlap or polyethylene sheets between finishing operations.

When should I be worried about cracks?

Severe – cracks up to 25mm wide could be a sign of structural damage and should be inspected and repaired by a professional. Very severe – any crack above 25mm in width indicates serious structural damage and will need major repair work, which could include underpinning and rebuilding.

How can you tell if a crack is structural?

The cracks run diagonally Jagged cracks that move in a diagonal direction or look like a set of stairs moving up your wall could be a sign of structural movement and may be slightly more serious than cracks that simply run up and down.

How do I know if my settlement is cracked?

1:1520:14How to identify & prevent Foundation Settlement Cracks - YouTubeYouTubeStart of suggested clipEnd of suggested clipAre the cracks formed when the stresses or forces exceed the capacity of the structural memberMoreAre the cracks formed when the stresses or forces exceed the capacity of the structural member structural cracks will endanger the safety of the building these cracks occur due to building settlement.

What causes plastic shrinkage cracks in concrete?

Plastic shrinkage cracking Plastic shrinkage is caused by the loss of water by evaporation from the surface of newly laid concrete or by suction of dry concrete underneath. At the surface, plastic shrinkage occurs when the rate of evaporation exceeds the rate of bleeding.

How do you stop plastic shrinkage from cracking?

Follow These Rules to Prevent Plastic Shrinkage Cracking Dampen the subgrade and forms when conditions for high evaporation rates exist. Prevent excessive surface moisture evaporation by providing fog sprays and erecting windbreaks. Cover concrete with wet burlap or polyethylene sheets between finishing operations.

What causes spider web cracks in concrete?

Cracks Caused by Premature Drying Crazing cracks are very fine surface cracks that resemble spider webs or shattered glass. They can happen on any concrete slab when the top loses moisture too quickly. Crazing cracks can be unsightly, but are not a structural problem.

What is thermal cracking in concrete?

Thermal cracking occurs due to excessive temperature dif- ferences within a concrete structure or its surroundings. The temperature difference causes the cooler portion to con- tract more than the warmer portion, which restrains the con- traction.

Why is plastic settlement cracking called that?

Plastic settlement cracks are so-called because they form while the concrete is still plastic i. e. it has not set. After it is placed in position, concrete undergoes a process known as ‘bleeding’. This process is a form of segregation where the water rises to the surface of the substrate, whilst the solids settle down.

What causes plastic to crack?

What causes plastic settlement cracking? As the name suggests, the cause of plastic settlement cracking is the settlement of the solid particles whilst the concrete slab is curing. The amount that a slab settles tends to be proportionate to the depth of the concrete i.e the deeper the concrete the greater the settlement.

Why is it important to increase the cover of concrete to reinforcement mesh?

Increasing the cover of concrete to reinforcement mesh minimises the likelihood of cracks forming at the surface.

What is cracking concrete?

Small or fine cracks identified on a concrete slab are generally deemed acceptable as part of minor settlement, weathering, or poor finishing of its surface. However, a competent building inspector should be able to not only classify the severity of the cracking, but also appropriately investigate the cause of the cracking. The following blog focuses on cracks that form as a result of what is known as plastic settlement cracking.

Why is it important to place concrete in a deep section?

Placing the concrete in deep sections first, such as beams, reduces the likelihood of differential settlement.

Does plastic settlement cause concrete to crack?

For example, as plastic settlement cracking may expose areas of the slab reinforcement mesh, the probability of concrete cancer is greatly increased. Also, as the creation of a void underneath the reinforcement mesh is also associated with plastic settlement cracking, any subsequent drying shrinkage may result in cracking through the full depth ...

Does a concrete slab settle with a restraint?

If there is no restraint during the placement of the concrete, such as reinforcing bar, then generally the slab settling will merely produce a slight lowering of the concrete surface. However, in a residential slab with reinforcing mesh for example, the effect of the settlement of the concrete slab over the restraint (the mesh) may produce a crack to form. This crack is identifiable as it generally follows the pattern of the reinforcing mesh.

Plastic settlement cracking

Soon after the concrete has been placed the heavy particles sink through the water and the water ‘bleeds’ to the surface. The initial shrinkage results from this compaction of the concrete as the excess water ‘bleeds’ to the surface.

Plastic shrinkage cracking

Plastic shrinkage cracks also appear when the concrete is plastic, usually a half to six hours after placement. These cracks are caused by the shrinkage of the surface regions of the concrete when the water that bleeds to the surface is allowed to evaporate too quickly after placement.

Early thermal contraction cracking

Early thermal contraction cracks appear at one day to two or three weeks after placement. Thermal cracks are a result of stresses brought about by temperature differentials. The usual cause of temperature differentials is the exothermic nature of cement hydration.

What causes plastic to crack?

Plastic shrinkage cracks are caused by a rapid loss of water from the surface of concrete before it has set . The critical condition exists when the rate of evaporation of surface moisture exceeds the rate at which rising bleed water can replace it. Water receding below the concrete surface forms menisci between the fine particles of cement and aggregate causing a tensile force to develop in the surface layers. If the concrete surface has started to set and has developed sufficient tensile strength to resist the tensile forces, cracks do not form. If the surface dries very rapidly, the concrete may still be plastic, and cracks do not develop at that time; but plastic cracks will surely form as soon as the concrete stiffens a little more. Synthetic fiber reinforcement incorporated in the concrete mixture can help resist the tension when concrete is very weak. Conditions that cause high evaporation rates from the concrete surface, and thereby increase the possibility of plastic shrinkage cracking, include:

How to prevent plastic from cracking?

Follow These Rules to Prevent Plastic Shrinkage Cracking 1 Dampen the subgrade and forms when conditions for high evaporation rates exist. 2 Prevent excessive surface moisture evaporation by providing fog sprays and erecting windbreaks. 3 Cover concrete with wet burlap or polyethylene sheets between finishing operations. 4 Use cooler concrete in hot weather and avoid excessively high concrete temperatures in cold weather. 5 Cure properly as soon as finishing has been completed.

How to keep concrete from shrinking?

Start curing the concrete as soon as possible. Spray the surface with liquid membrane curing compound or cover the surface with wet burlap and keep it continuously moist for a minimum of 3 days. Consider using synthetic fibers (ASTM C 1116) to resist plastic shrinkage cracking.

How far apart do plastic cracks appear?

These cracks appear mostly on horizontal surfaces. They are usually parallel to each other on the order of 1 to 3 feet apart, relatively shallow, and generally do not intersect the perimeter of the slab. Plastic shrinkage cracking is highly likely to occur when high evaporation rates cause the concrete surface to dry out before it has set.

What to use to cover concrete?

If delays occur, cover the concrete with moisture-retaining coverings, such as wet burlap, polyethylene sheeting or building paper, between finishing operations.

Can plastic shrinkage be minimized?

Plastic shrinkage cracks are unsightly but rarely impair the strength or durability of concrete floors and pavements. The development of these cracks can be minimized if appropriate measures are taken prior to and during placing and finishing concrete.

Do concrete cracks form when it dries?

If the surface dries very rapidly, the concrete may still be plastic, and cracks do not develop at that time; but plastic cracks will surely form as soon as the concrete stiffens a little more. ...

What is Plastic Cracking of Concrete? Its Occurrence, Causes, and Preventive Measures

What is Plastic Cracking of Concrete? Its Occurrence, Causes, and Preventive Measures

Occurrence of Plastic Cracking

Plastic shrinkage cracks & plastic settlement cracks occur within a few minutes or hours of concrete laying and finishing. Plastic shrinkage cracks and plastic settlement cracks occur when concrete is still in a plastic state and has not fully hardened.

Causes of Plastic Settlement Cracking

The main causes of plastic settlement cracks can be summarized briefly as below:

Causes of Plastic Shrinkage Cracking

The main causes of plastic shrinkage cracks can be summarized briefly as below:

Preventive and Protective Measures

The restraints which lead to plastic settlement cracking are generally an inherent part of the construction and can’t be totally avoided. The cracking can be reduced only by increasing the cohesiveness of the concrete and reducing the bleeding of the concrete.