The settlement tank has an inlet to allow the drilling fluid into the chamber where it sits before flowing to the next tank. The purpose of the tank is to allow the fluid to rest for a while as the waste material settles out. It is an extremely important process that allows the drilling fluid to be reused by circulating it back into the borehole.

What is the settlement rate of a tank?

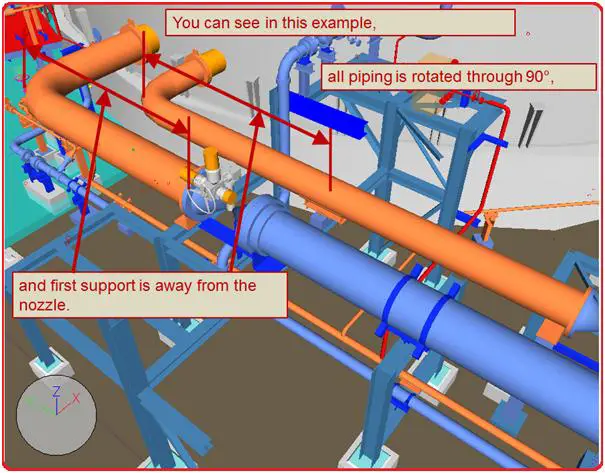

Majority of the total settlement occurs during hydro test of tank (before piping is connected). This is generally permanent. … Typically 60% For balance 40% of settlement, this occurs after piping connection, piping needs to be designed properly with settlement effect. IN CASE OF CLAY: Progressive settlement.

Does tank settlement affect the stress analysis of piping system?

In this article I will describe about the effect of tank settlement on stress analysis of piping system connected to large tanks. Equipment diameter is small (up to 3m). Therefore it is possible to design its foundation with large raft (say 10 m), to minimize or have insignificant settlement.

How many times is settlement mentioned in API 653?

In fact, the word “settlement” is mentioned more than 250 times in the API 653 standard. As an inspector, you should be able to determine the type and extent of tank settlement, and decide if it can affect tank integrity. In the api 653 exam, maybe 2 questions will show up about this subject.

Where to place the settlement of a tank?

The settlement is more at the centre of tank, and typically 50% at the edge of tank. Since our nozzles and tank roof are connected / supported on shell, that is on outer edge of tank, we need to consider the settlement at outer edge of tank.

What causes solid loss in a final settlement tank?

As discussed previously, solids loss from a final settlement tank, caused by plant failure, can easily be mistaken for a bulking or foaming incident. The effects of a pump failure or blockage can look very similar to that caused by a bulking or foaming sludge (i.e. rising sludge blanket or floating solids on the final tank). Filamentous microorganisms are present in most activated sludges in varying amounts and their presence does not necessarily mean that they are the cause of the solid loss. Correctly identifying the dominant filaments and getting a measure of their abundance is the first step in establishing this. Furthermore, an understanding of the mechanisms and drivers behind the predominance of filamentous microorganisms in the biomass will lead to control strategies for their eventual elimination.

Where is flow introduced in a gravity settlement tank?

After the coagulation and flocculation stages, flow is introduced upward through a “sludge blanket” in the lower part of a gravity settlement tank. Though provision of a delay time between coagulant and polymer addition is essential, this is sometimes omitted in error. Good flow distribution across the tank bottom is key. The tank may be rectangular or circular, inclined or hopper bottomed.

How does floc affect effluent?

In the simplest design of horizontal flow tank, floc is allowed to accumulate on the floor of the tank until such time as the increasing velocity of water above the accumulated sludge begins to stir it up, thereby affecting the clarity of the effluent. When this occurs the tank should be cleaned out.

What are the advantages of a circular water tank?

The advantages of these tanks are: greater tolerance to hydraulic and quality changes, ideal for stop/start operation; infinite turn down; simplicity of operation; suitable for water containing high silt loads; and performance is not appreciably affected by diurnal temperature change. The primary drawback is their low surface loading rate and hence the large footprint and associated capital costs. Compared to rectangular tanks, circular tanks do not lend themselves to a compact layout. One such circular tank design known as Centrifloc ® is used for the treatment of R. Tigris water at the 1365 Ml/day Al Karkh water treatment works in Baghdad and is shown in Figure 7.2.

How many tanks can a pump serve?

Pumps related to storage can be grouped or located individually to serve one or two tanks. Groups of pumps will facilitate centralized operation but may require long suction piperuns. Lines carrying hot, cold, or flammable materials should be as short as possible, consistent with accommodating thermal stresses.

Why should tanks not be elevated?

Tanks containing flammable substances should not be elevated to provide gravity discharge because of the difficulties of stopping flows under fire conditions. Overhead piperacks should be kept to a minimum in bunded areas and pipes should be run in banks at grade on sleepers ( Figs. 10.2 and 34.2 ).

What is the second example of evaluating circumferential differential settlement?

11.15. The curves are shown in Fig. 11.18.

What Does Settlement Tank Mean?

A settlement tank is a compartment that allows solid content such as sand and cuttings to precipitate and sink to the bottom.

How is drilling fluid circulated?

The circulated drilling fluid is first passed through the shale shaker before entering the settlement tank. The received fluid is not stirred and allowed to rest.

Can barite settle in tank?

Since there is a possibility of the weighting agent barite also settling in the tank, a provision for bypass ing the undersize screen discharge slurry directly to the next processing compartment is advisable.

What causes settlement in a tank?

Settlement can be caused by the following: Lack of support under the base circumference affecting the cylindrical shell and the tank bottom. Parts or the concrete ring may be lost. Non homogeneous geometry or compressibility of the soil deposit (voids or crevices below the bottom plate)

What causes a tank to settle?

Settlement can be caused by the following: 1 Lack of support under the base circumference affecting the cylindrical shell and the tank bottom. Parts or the concrete ring may be lost. 2 Non homogeneous geometry or compressibility of the soil deposit (voids or crevices below the bottom plate) 3 Non uniform distribution of the load applied to the foundation. Differential pressure during emptying and filling cycles 4 Uniform stress acting over a limited area of the soil stratum 5 Wrongly constructed foundations (deficient reinforcement of the concrete, bad quality cement, etc) 6 Liquefaction phenomenon around the foundation generated by earthquakes. Consider the following excerpt:

How many times is settlement mentioned in API 653?

In fact, the word “settlement” is mentioned more than 250 times in the API 653 standard. As an inspector, you should be able to determine the type and extent of tank settlement, and decide if it can affect tank integrity.

What is edge settlement?

Edge settlement occurs when the tank shell settles sharply around the periphery, resulting in deformation of the bottom plate near the shell-to-bottom corner junction, or the depth of the depressed area of the bottom plate. You can see a diagram for edge settlement below.

What is localized bottom settlement?

Localized bottom settlement remote from tank shell are depressions (or bulges) that occur in a random manner, remote from the shell. The same equation (B3.3) used for bottom settlement near the tank shell can be used for the evaluation of this kind of settlement, granted the bottom has single-pass welded joints.

What happens if there is no settlement expected?

If there is no settlement expected (for example, a tank over a giant rock), it might not need settlement measurements, but that´s a decision that is entirely up to the owner. In normal conditions, there will always be settlement.

How to turn edge settlement into bew?

1. If edge settlement is in an area with a welded seam than runs parallel +-20° to the shell, B turns into Bew. 2. If edge settlement is in an area with a welded seam than runs perpendicular +-20° to the shell, B turns into Be . STEP 2.